THE ZEBRA MUSSEL PROBLEM

Mussel Stop

For many years now, the zebra mussel (Latin: Dreissena polymorpha) has been proliferating in rivers and lakes around the globe. For industry, its strong growth means economic damage in the millions. From river and lake water, zebra mussels enter the cooling water circuits of industrial plants, where they interfere with the functioning of plate and tube heat exchangers. In the past, the mussels and their larvae were usually killed using chemicals and then flushed out of the pipe system. However, in addition to being highly damaging to the environment, this method is also very costly. Mechanical filter systems with the MUSSEL STOP system from DANGO & DIENENTHAL offer a highly effective means to control the mussels when they are only in the larval stage.

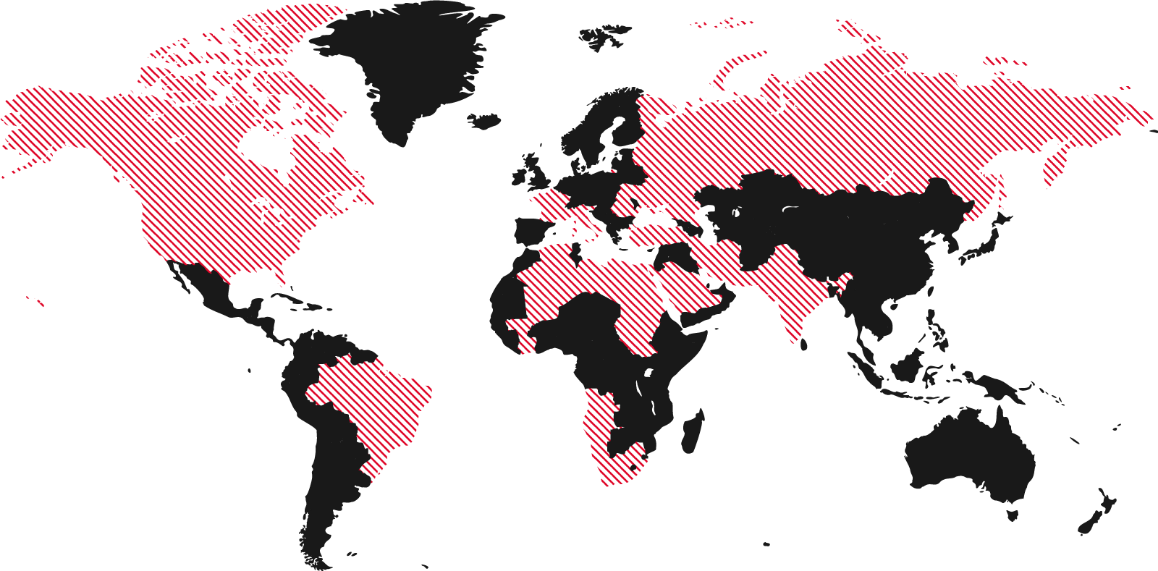

THE SPREAD

Like its close relative, the quagga mussel, the zebra mussel was originally native to the waters of western Asia. Today, the species is known and often feared on all continents. In all likelihood, the larvae of these generally otherwise useful animals were distributed throughout the world's oceans in the ballast water tanks of large cargo ships. Industry was unprepared for the rapid growth and spread of mussel larvae.

The potential danger and the resulting damage have only gradually been subjected to a realistic assessment. Today, power plants, steel mills, and chemical companies suffer enormously from infestations of these sea- and river-dwelling animals, which multiply in the cooling water and incapacitate entire pipe systems and heat exchanger systems – causing damage amounting to several million euros/dollars year after year.

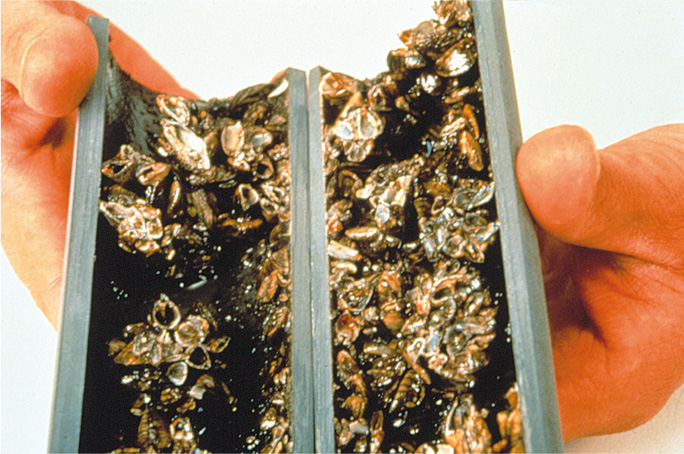

THE DEVASTATING CONSEQUENCES

In foreign ecosystems, the zebra mussel has few natural enemies. It therefore reproduces quickly and uncontrollably. Once a population has established itself in a lake, it is virtually impossible to prevent thousands of tiny mussel larvae from being pumped into the cooling water circuits of local industrial plants along with the industrial cooling water. These grow to a size of 200 μm in pipe systems within 8 days, accumulate in and block heat exchangers, spray nozzles, and even entire pipelines.

As a result, production equipment can no longer be cooled. After a certain amount of time, this problem generally results in an inevitable shutdown of the plant in order to eliminate the risk of machine damage. The operator then not only has to bear the consequential costs of the production stop, but also has to remove the mussels from the cooling circuits before production can be resumed. This in turn ties up manpower and also entails high costs.

The high acceleration in DANGO & DIENENTHAL Filterautomats ultimately causes the death of mussel larvae.

The advantages at a glance

- Death by collision

- Negative pressure and separation at the sieve edge due to increased flow velocity

- Destruction by negative pressure

- Deformation and damage by high acceleration

The MUSSEL STOP system from DANGO & DIENENTHAL can effectively prevent mussel infestation in cooling systems used in all industries. The high level of effectiveness of a Filterautomat, Backwash Drum Filter or JET Filter fitted with the MUSSEL STOP system results from a unique gap geometry with a filter fineness of about 300 μm. The optimum ratio of flow rate to filter area in such filters allows for very high filtration velocities. In combination with the geometry of the filter element, this ensures the high acceleration of the mussel larvae. The very high acceleration forces acting on the microorganisms ultimately cause the death of the larvae. Corresponding tests have shown that the acceleration force must amount to at least 1,000 g in order to effectively kill mussel larvae. This is guaranteed with the use of a MUSSEL STOP Filterautomat, Backwash Drum Filter or JET Filter from DANGO & DIENENTHAL.

LOW-MAINTENANCE OPERATION

For the effective control of mussel larvae, high backwash velocity is just as desirable as high filtration velocity. Many filter systems with excessively large filter areas have neither of these. As a result, mussels, sand, and other solids that have settled in the filter element cannot be cleaned off during backwashing.

The optimal ratio of flow rate to filter area of a Filterautomat or JET filter fitted with MUSSEL STOP also offers advantages here: Backwash speeds of up to 10 m/s ensure the effective cleaning of the filter element and thus the low-maintenance operation of the entire plant.

GET MORE

DOWNLOAD

PRODUCTS WITH MUSSEL STOP

FILTER MORE

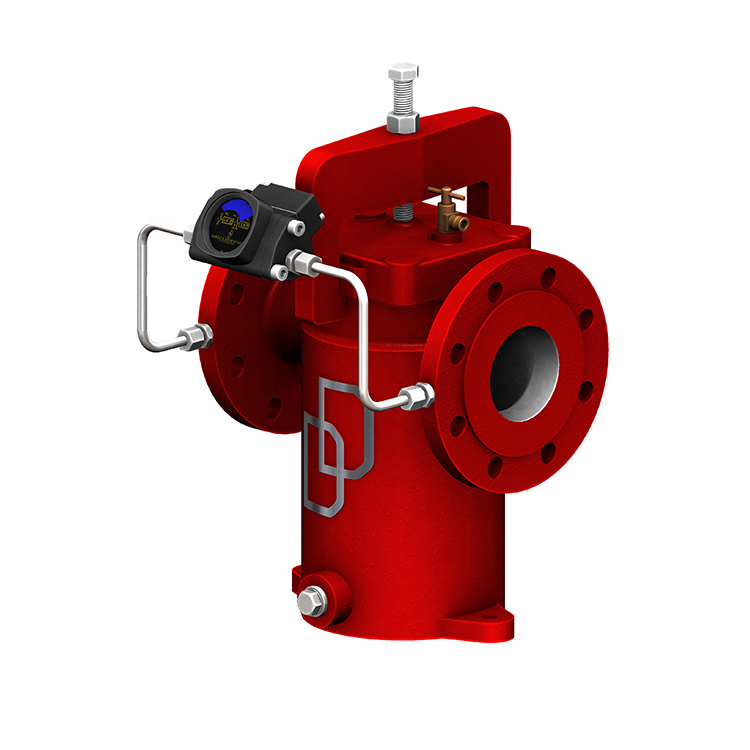

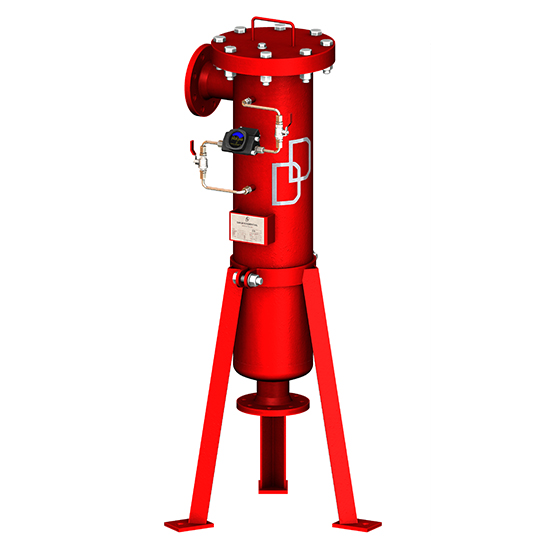

Filterautomat

Extremely robust automatic filter

The Filterautomat boasts an extremely robust design and excellent backwash performance. The rotating filter drum distributes any solids uniformly over the entire filter surface and filters it out effectively.

Backwash Drum Filter

Automatic filters for the most difficult media

The Backwash Drum Filter is based on the filtration and backwash principle of the Filterautomat. A more customized selection of materials is possible for the most difficult media.

Backwash Drum Filter S

Compact automatic filter for the most difficult media

This filter impresses with excellent backwash performance and a compact design. A customized selection of materials is possible for the most difficult media.

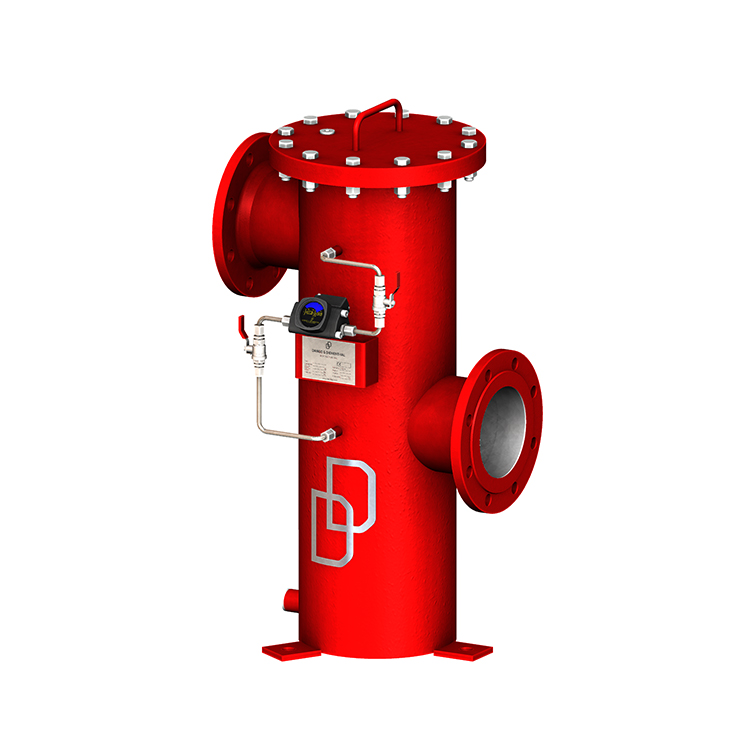

JET Filter

Automatic filter with no moving parts

The JET filter is an inline filter without any moving internal parts. Its patented design enables very high flow rates, a high diversity of materials and flexible installation in pipelines.

JET Filter S

Compact automatic filter with no moving parts

Due to its electronic controller, the JET Filter S is immediately ready for use as a complete module. The filter element can be exchanged without removing the filter.

Plate Filter

Massive inline filter for coarse filtration

The plate filter is a solid inline filter with an inclined filter plate. Both manual and automatic backwashing is possible with this model.

Single Filter 15

Manual filter – pure and simple

This manual filter separates particles from the volume flow with the aid of a filter basket.

Single Filter 30

Manual filter with a high diversity of materials

This manual filter separates particles from the volume flow with the aid of a filter basket. It impresses with a larger filter area.

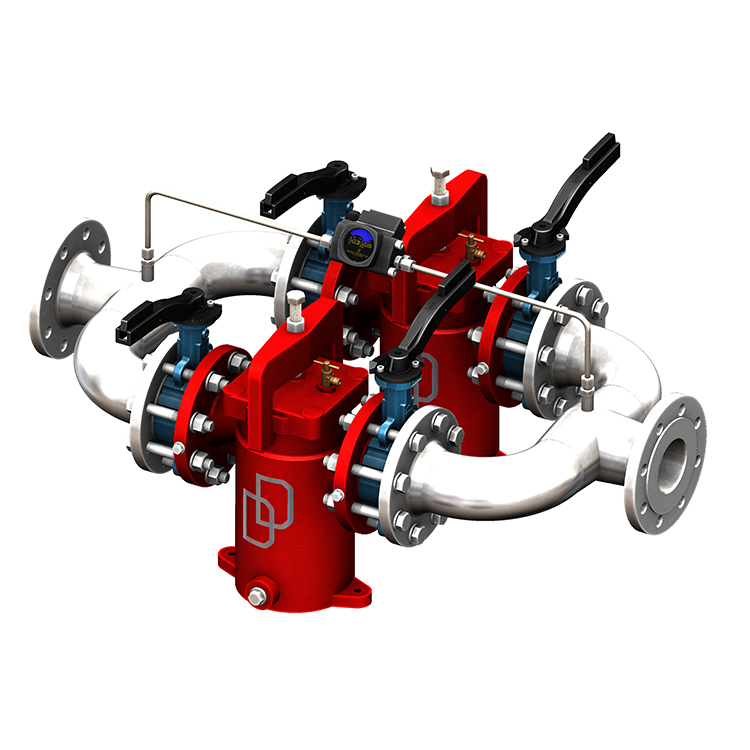

Duplex Filter 20

Continuous filtration with manual switching

The Duplex Filter 20 features four shut-off valves that allow the selection of which filter should be switched to operation and which to standby. This enables continuous filtration with no interruption of operation.

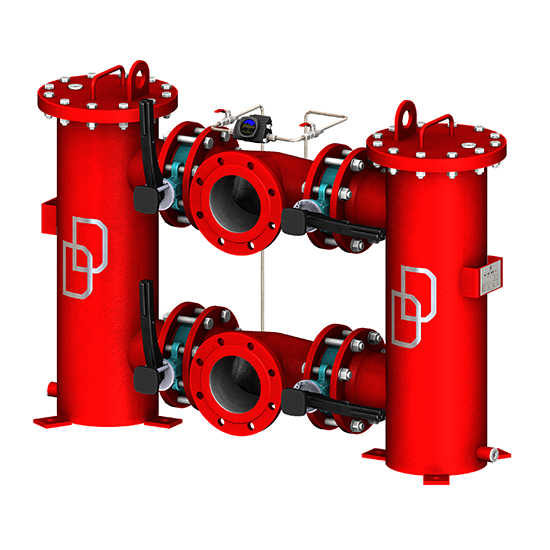

Duplex Filter 40

Continuous filtration with a high diversity of materials

The Duplex Filter 40 features a switching unit that allows to select which filter should be switched to operation and which to standby. This enables continuous filtration with no interruption of operation.

Bag Filter

Manual filtration down to 1 Micrometer

The filter element of this manual filter can be made of different materials, such as nylon or needle felt.

Multi-Bag Filter

Bag filter for higher flow rates

The Multi-Bag Filter includes multiple filter bags integrated into a single filter housing. This allows higher flow rates and longer operating times.

SLUDGE DEWATERING DEVICE

For backwash water treatment

A filter box bag retains coarser particles inside the Sludge Dewatering Device. The bottom can be swung open to allow the easy disposal of the filter box bag and its contents.

Separator

Filter with centrifugal separation

A turbo disk in the inlet sets the volume flow into rotation. Centrifugal forces ensure particle separation.

Project request

Are you planning a new project? Then let us support you. If you give us information about your requirements and the boundary conditions, our experts will be happy to contact you.

Ask for more